China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

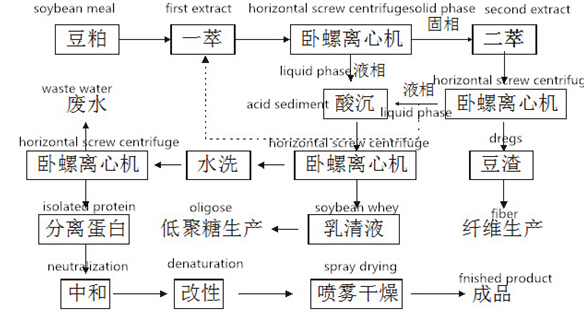

Isolated Soybean Protein Meal Manufacturing Process

The soybean meal is transported from outside and palletized in the newly built storage. Unpack the meal and pour them into charging hopper. The air blower conveys them to the feeding bin on the extraction tank.

The soybean meal in the feeding bin is continuously conveyed to the first extraction tank by gravity weighing feeder. Meanwhile, the water, NaOH and the defoamer are added to the tank. The protein dissolves in the water. To help protein dissolve, we use secondary first process extraction with emulsification pump for conveying.

The suspension liquid is pumped out to horizontal centrifuge where the liquid phase is discharged from the end of the machine to the recycling tank while the solid dregs with dilution water is conveyed to the second process extraction tank.

The solid phase after second process extraction is pumped to centrifuge where the liquid is flowed to first process extraction tank and the dregs are conveyed to slag dump by spiral conveyor.

The protein liquid separated from the first process extraction is pumped to decanting tank and then out. The HCL is added to the withdrawal tube in a proportion. The pumped liquid is conveyed to the depositing tank where the protein forms into curd. Then the materials are pumped to the horizontal screw centrifuge and heated in the tube with steam injected. Water soluble materials are discharged to waste water pool while the insoluble with substantial protein concentrate is discharged out of the solid phase outlet in cake shape curd and conveyed to water washing tank after forming into slurry with water.

In the water washing tank, the soluble materials is further released from the protein curd. Then they are pumped to the horizontal screw centrifuge where the soluble is discharged to the waster water pool while the insoluble with substantial protein concentrate is discharged out of the solid phase outlet in cake shape curd after forming into slurry with water. The curd is pumped to neutralization tank where water and NaOH are added to adjust the pH and solid content. The curd in the neutralization is pumped to homogeneous tank where the material is heated by sprayed steam and kept for some time in the disinfection tube. The disinfected slurry is flash cooled in the vacuum tank.

The curd is pumped to the high pressure pump which conveys the them to the cocurrent spray drying tower. The hot wind of the nozzel quickly dries the curd into powder. The dried protein is discharged out by cyclone separator while the meal is pneumatically conveyed to finished product storage for weighing, packaging, heat sealing and sack closing. Then they are conveyed to warehouse after being metal detected.