QMJ300D*4 Buckwheat Dehuller Machine

Buckwheat dehuller machine working process: Buckwheat dehuller machineadopts Japanese technology. It has high hulling ratio with less broken rate; Clearance between emery roll can be adjusted, which ensures the effect of hulling ratio. Buckwheat raw materials should be processed by cleaning and classifying before shelling. The mudstone, soil, large and small impurities is removed first by multifunctional shaker.Then the material is conveyed to the classifying screen by bucket elevator for classifying. After this, it can enter into the buckwheatshelling machine.

Buckwheat dehuller machineis equipped with two emery rollers (lower and upper roller). When the raw material flows into the husking chamber, the high-speed rotating emery rollers cut and rub the buckwheat cortex continuously, which destroys the bonding strength between buckwheat shell and kernels. In this way, buckwheat husk is removed. After hulling, the buckwheat is processed by windmill screen, then enters into classifying screen. By vibrating and sorting, the buckwheat kernels and husks are separated and then the finished products are packaged. The unhulled buckwheat is sent back to the huller for continuous shelling.

Buckwheat dehuller machine technical parameter:

| Model | Capacity kg/h |

Main motor power kw |

Rated voltage v |

Dimension mm |

|---|---|---|---|---|

| HTQM-30 | 150 | 1.5 | 380 |

920*710*1556 |

| HTQM-30x2 | 300 | 3.2 | 380 | / |

| HTQM-30x4 | 600 | 6.8 | 380 | 2200*817*2384 |

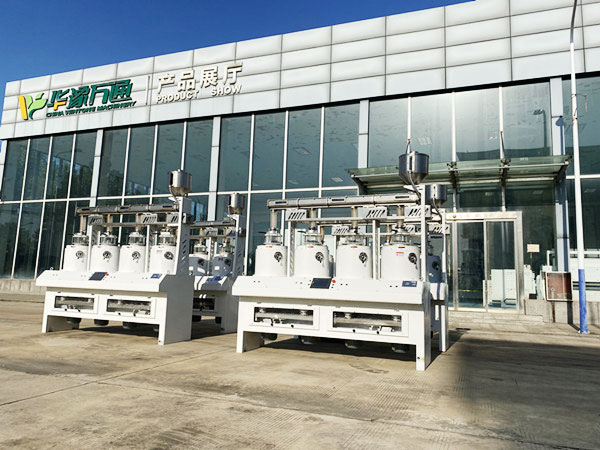

Factory

Workshop

Exhibition

Customer Visit

Our Team

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

- Win Tone will attend the 96th Agricultural and Commercial Show in Zambia

- Global Agents & Distributors Wanted!

- The Statement

- WELCOME TO THE 42ND DAR ES SALAAM INTERNATIONAL TRADE FAIR (DITF)

- Welcome to the 11th Agriculture and Food Exhibition (AGRIFEX- ETHIOPIA)

- Bean Skin Peeling Machine at Argentine Equipment Exhibition

- Welcome to the 123rd Spring Canton Fair 2018

- The Spring Festival Holiday (February 13th—February 22nd) Announcement

- Share Incentive Conference for Zhengzhou Branch of Win Tone Group Was Held Successfully