China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

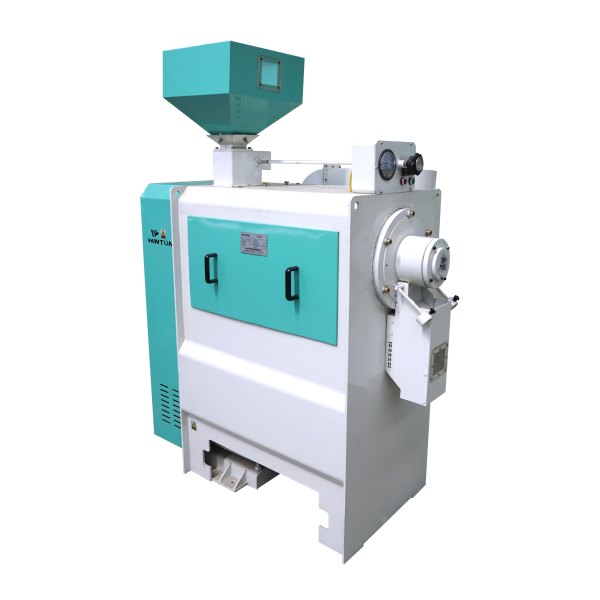

MTPS-R Series Emery Roller Corn Peeling Machine is a professional and efficient machine for removing black navel, completely solving the pain point of black star in corn processing production lines. It is a new corn processing production line peeling and dehulling equipment, an upgraded old corn processing production line peeling and dehulling equipment, a peeling and kernel making equipment for small corn processing plants, and a peeling and mold removal equipment for feed processing production lines.

The yield rate of this device is 5-10 percentage points higher than similar products in the market, significantly increasing the economic benefits of the enterprise; Energy consumption is 10-15 percentage points lower than similar products in the market, which is energy-saving and environmentally friendly; Adopting locking self-aligning bearings for easy maintenance, installation, and disassembly; Non boring machine frame, easy to adjust for excellent mechanical performance; Spindle jet fan can effectively reduce the temperature rise of grain crops; The split type sieve frame allows for quick replacement of sieve plates.

Working Principle

The new MTPS-R Series Corn Milling Machine adopts the "dry cutting and peeling" technology, which can achieve layered fine cutting and peeling of corn endosperm and one-time peeling of embryo, thus achieving low crushing rate and good peeling effect on corn. The primary purification rate is 60%, and the secondary purification rate is over 95%. At the same time, compared to traditional peeling machines, with the same power, the output can be increased by 1.5-2 times, saving energy and reducing consumption, rapidly increasing the profit point of corn processing enterprises.

Performance Characteristics

1. The corn flour milling machine adopts diamond rollers and sieve plates, which have a longer lifespan;

2. Efficient peeling, blackening, and embryo removal, high yield of finished products, complete and shiny finished particles;

3. With high output, low energy consumption, high efficiency and energy saving, and small footprint, it is a specialized machine for corn processing production lines and corn feed processing industries;

4. The emery roller can run continuously for more than 8000 hours, and the diamond sandblasting screen plate can run continuously for more than 6000 hours, with durability and cost savings.

Finished Product

Technical Index

Type

Yield(t/h)

Power(kw)

Air Suction(m³/h)

Wind Pressure(pa)

One Peeling Rate(%)

Twice Peeling Rate(%)

Weight(kg)

Dimension(mm)

MTPS18R

2-2.5

18.5-22+2.2

800-1200

3660-3720

65

95

760

1935×735×1892

MTPS25R

3-4

22-30+2.2

1000-1500

3660-3720

65

95

805

2013×693×2222

MTPS30R

4-6

37-45+2.2

2600-3400

4500-5500

65

95

1050

2191×950×2222

MTPS25R×2

6-8

44-60+3

4000-6000

1800-2100

65

95

1500

2033×1450×2222

MTPS30R×2

8-12

74-90+3

5000-7000

4500-5500

65

95

1950

2332×1450×2222