China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

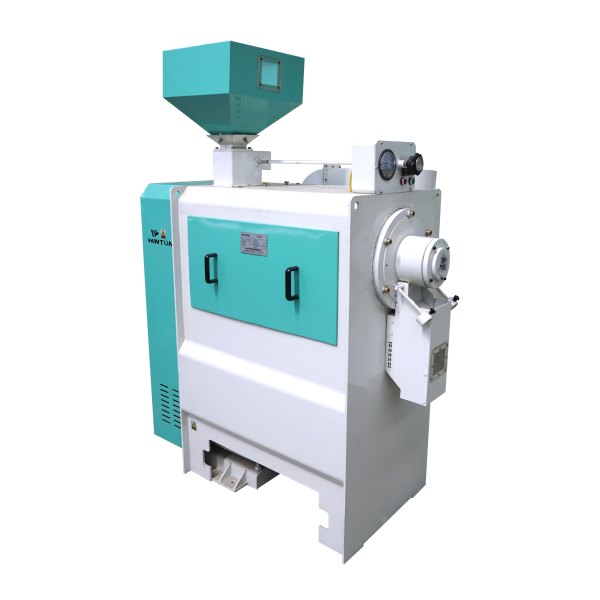

The fine corn hulling machine is used in the peeling and germ removing section in corn processing industry, and the preliminary cleaning section of breweries and feed enterprises.

The material is sent by the screw propeller to the center part of the fine corn hulling machine, the hulling chamber. Then it utilizes emery roll that rotates with high speed to cut and rub the corn bran continuously and destroys the bonding strength between the maize bran and the corn endosperm and the germ, which makes corn bran separated. Then the material is conveyed to the discharging port and the hulling process is finished.

MTPS-25R Fine Corn Hulling Machine Features

1. Inside of the fine corn hulling machine installs the air draft dedusting system, which ensures the best sanitation condition. MTPS-25B fine corn hulling machine connects with highly efficient air indraft system, which ensures reliability of maize bran discharging.

2. Fine corn hulling machine's sieve plate and other accessories are quick-replaceable. It has durable emery roll and less wearing parts. This feature makes fine maize huller easily operated and maintained.

3. Fine corn hulling machine has uniform end products and reliable quality. It can adjust feeding speed and outlet pressure to increase the friction and pressure in the peeling chamber so as to produce high quality end products.

4. It has moderate peeling process and high processing efficiency. Stable corn flow and the efficient air indraft system inside of the machine makes the peeling process moderate so as to reduce corn loss in processing and ensures the profit maximization.

Finished Product

Technical Parameter

Type

Capacity(t/h)

Air Volume(m³/h)

Power(kw)

Weight(kg)

Dimension(mm)

MTPS-25R

2.5-3.5

1800-2100

30

1000

1515×1220×2100