China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

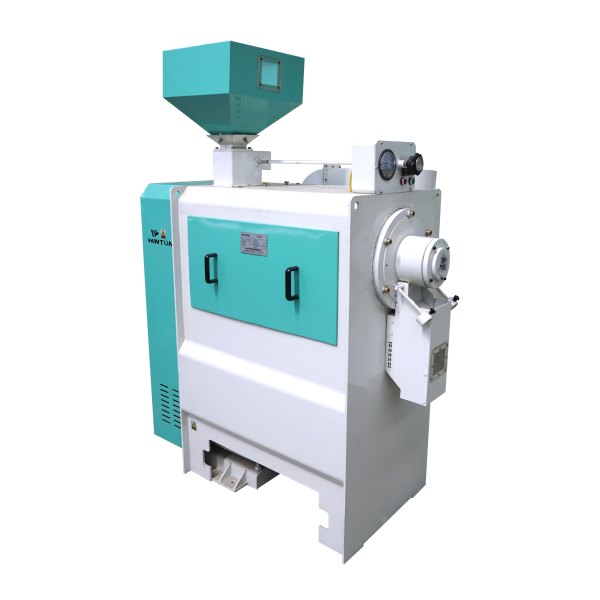

MTPS-25A Corn Peeling Machine is newly improved through wide market investigation along with advantages and experiences from home and abroad. It is mainly used in maize and coarse cereal processing plant for maize hulling and polishing. The MTPS series corn peeling machine adopts the "dry cutting peeling" technology, which can achieve layered fine cutting peeling of corn endosperm and one-time peeling of embryo, the first peeling rate is 60%, and the second peeling rate is over 95%.

Working Principle of Corn Peeling Machine

The corn goes in the propelling chamber through charging regulation device where the spiral pusher conveys them to emery roll whose sharp appearance cuts the bran at a speed, making the maize particles rub against the sieve plate, so as to dehull the materials. The outlet is equipped with air suction inlet to further cool down the corn and clean the finished product for the second time.

Performance Advantages

1. Using diamond rollers and sieve plates, durable and long-lasting;

2. High yield, minimal breakage, and intact and shiny finished particles;

3. With high output, low energy consumption, high efficiency, and energy saving, it is a specialized machine for corn processing production lines and corn feed processing industries.

Finished Product

Technical Parameter

Type

Capacity(t/h)

Air Volume(m³/h)

Power(kw)

Weight(kg)

Dimension(mm)

MTPS-25B

2.5-3.5

1800-2100

30

1000

1515×660×2100