China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

Lentil Peeling and Splitting Production Line can remove the bran of various beans, such as lentil, soybean, peas, mung bean, kidney bean, lupin beans, black eye beans, chickpea, etc. Win Tone Machinery 100TPD lentil processing plant ordered by the Canadian customer mainly consists of cleaning, peeling, fine selection and packaging. It adopts storey building structure and has the features of advanced technology, strong specificity, reasonable layout, low energy consumption, high yield, low breakage rate, automatic and continuous production.

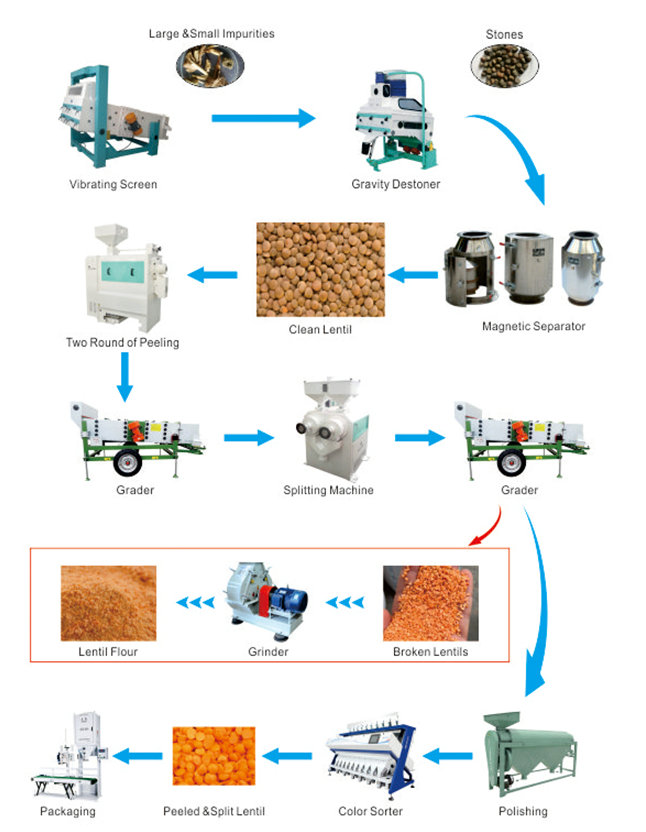

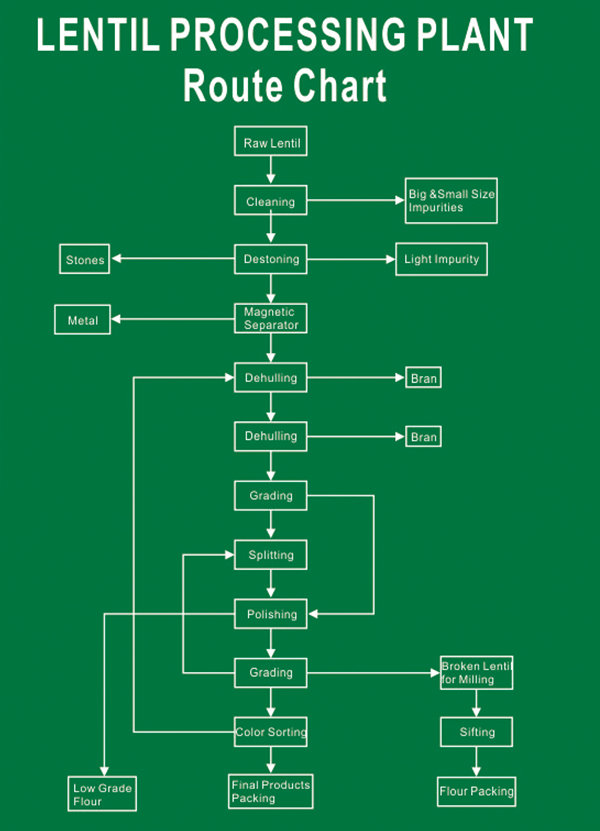

Technological Process of Lentil Peeling and Splitting Production Line:

1. Lentil cleaning section: it adopts two screening sections, two destoning sections, one magnetic separation section, and removes the big, small and light impurities, pebbles and magnetic material from the beans to ensure the quality of the end products.

2. Lentil color sorting section: it adopts the color sorter to separate the moldy kernels, shriveled beans and foreign species of beans according to the color and luster feature of the beans.

3. Lentil peeling and splitting section: it adopts peeling, splitting, brushing and shunting technology (it can utilize the segregation valve to choose peeling and brushing according to the material character.)

1)Peeling and splitting: it can remove the bean bran, split the bean kernels and separate and collect corn kernels by effective aspiration system;

2)Brushing: it can separate the micro bran and dust which adheres to the material surface.

4. Grading section: it adopts different screens and classify the material into different grades according to the size.

5. Lentil kernel making and grits milling section: it adopts the technology of three peeling sections, one grits making section, grading and suspension.

1)Peeling section: it can remove the bean bran and separate and collect it by effective aspiration system and produce peeled kernels;

2) Bean grits making section: it uses fine bean grits machine and mill beans into bean grits;

3) Bean kernels and bean grits grading section: it adopts different screens and classifies bean kernels or bean grits into different grades according to the size.

4)Suspension: it separates bean bran by utilizing airflow according to different material gravity.

6. Lentil flour milling section: it adopts the technology of burdening, several processes of grinding and screening and grading.

1)Burdening: it can mix different material according to different requirements for different products;

2)Grinding: it can grind or mill the beans into fine bean flour by the professional bean grinder;

3)Screening: it separates the bean flour.

7. Measuring and packaging section: storage can reduce the amount of labor used. Measuring can be artificial or electronic.

Bean bran removing machine end products:

Peeled Lentil:

Peeled Mung Bean:

Peeled Chickpea:

Peeled Peas:

Lentil Peeling and Splitting Production Line Technical Parameter:

Type

Power(kw)

Power Consumption(kw/h)

Capacity(t/24h)

Workshop Dimension(L*W*H/M)

10t

24

38-40

10

10*4*4 (steel structure)

20t

56

38-40

20

16*5*5 (steel structure)

30t

72

38-40

30

20*5*5 (steel structure)

50t

119

38-40

50

20*5*7 (steel structure)

100t

238

38-40

100

30*5*7 (steel structure)

China Win Tone Machinery has been specializing in lentil processing project design, manufacture and research for about 30 years. Our lentil processing plant has been exported to Ethiopia, Kenya, Indonesia, North Korea, Iran, Canada and etc. We have our own professional technicians team and installation team. We can help you realize the one-stop purchasing service from design, manufacture to installation.

Canada 120T/Day Lentil Peeling Project:

24T/Day Mung Bean Peeling Line in Thailand:

2T/Hour Lentil Peeling Line in Russia:

1T/Hour Lentil Peeling Line in Ethiopia:

Pakistan 20 Sets of Chickpea Peeling Machines Delivery:

Our Service