China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

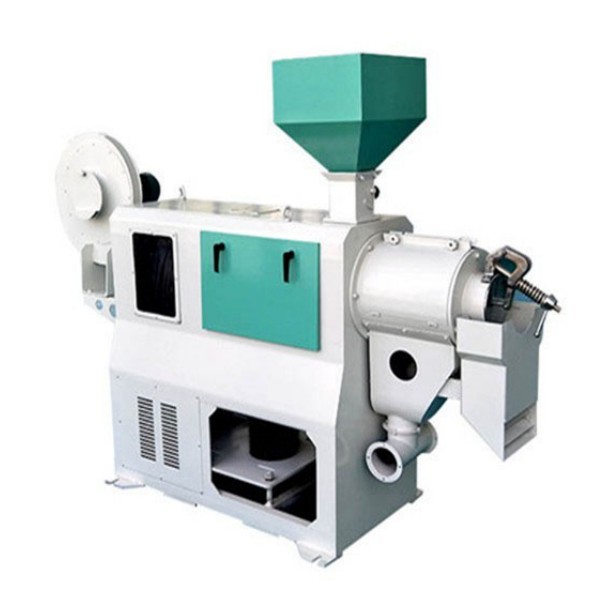

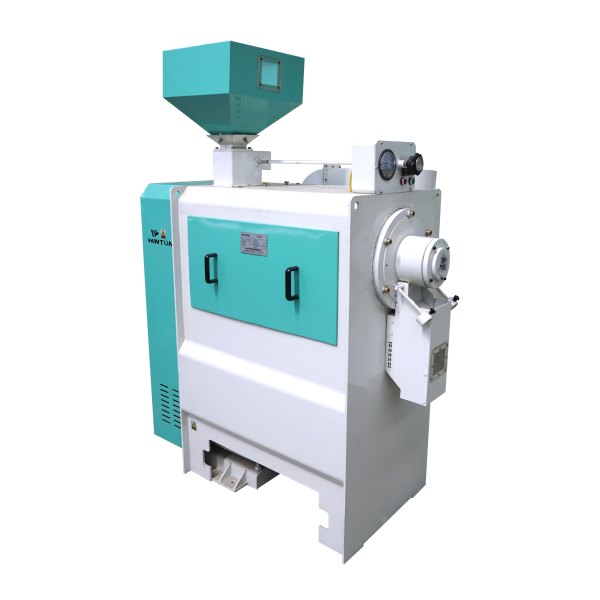

MPGT17 Iron Roller Corn/Maize Peeler and Polisher mainly has functions of corn, wheat, barley and paddy peeling and polishing. It can process corn into edible corn kernels and also processed into feed.

Working Principle

1. After cleaning up, the unprocessed corn enters into the peeling chamber of corn peeler and polisher machine through feeding port.

2. By control the feeding speed at the feeding port and the pressure of the pressure valve, we make the peeling chamber have some pressure. The machine squeezes, peels, degerminates, removes impurities and polishes the material between the rotary roller and the screen.

3. And under the pneumatic effect, the corn kernels and the bran separate automatically and then we can get qualified corn kernels. The machine is internally installed efficient air suction device, which can remove the bran and impurities from the peeling process.

Features

1. Various model and capacity available

This series of maize peeler and degerminator has 5 models of different sizes. After new product upgrades, the double-body 6-8 tons per hour equipment is specially launched.

2. health and safety

The fine chaff is absorbed by the chaff collector, with low dust concentration, hygienic and safe.

3. Simple and convenient operation

No need to disassemble the spindle for belt change, easy to operate and maintain

4. Wide range of applications

It is an ideal corn grain machine for the upgrading of small and medium-sized corn deep processing industries. It is also widely used in rice-making industry through improvement.

Finished Product

Technical Parameter

Type

Capacity(t/h)

Power(kw)

Rated voltage(v)

Weight(kg)

Dimension(mm)

MPGT-17

3-4

30-45

380

510

1630×1272×2435

MPGT-17×2

6-8

37×2+3

380

840

2563x1490x2204