China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

The most critical part of quinoa processing is the removal of saponins from the outer layer of quinoa. Since saponins have a bitter taste and are mildly toxic, they must be eliminated before consumption. The key challenge lies in thoroughly removing saponins without damaging the quinoa's shape or nutritional value.

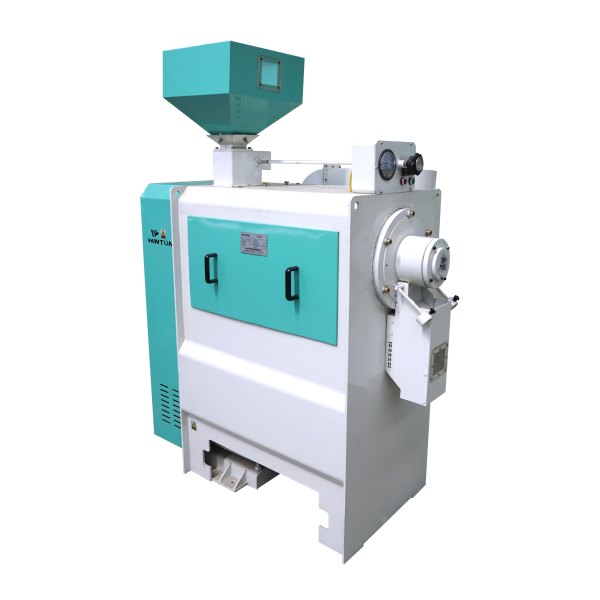

Based on the structural characteristics of quinoa, WinTone machinery has developed specialized quinoa peeling machines and quinoa polishing machines, which have been applied in fully dry quinoa processing lines. This innovation improves upon the traditional South American wet-processing method involving water washing. The optimized equipment has been deployed in domestic regions such as Inner Mongolia and Yunnan, as well as in international markets including Canada.

Characteristics of Process Design:

1. Fully Dry Processing Technology: Dry processing effectively preserves quinoa's nutritional value, reduces water consumption, eliminates the need for drying, protects the environment, and enhances the product's market competitiveness.

2. High Quality Finished Products: WinTone’s patented sand-roller quinoa peeling and polishing machines not only improve the yield of finished products but also enhance their quality. The processed quinoa has a clean surface with minimal loss of its natural flavor.

3. Intelligent Control System: The MTPS Series Quinoa Peeling Machine incorporates high-efficiency dust removal and an automated control system, ensuring precise quality control.

Finished Product

Technical Index

Type

Yield(t/h)

Power(kw)

Air Suction(m³/h)

Wind Pressure(pa)

One Peeling Rate(%)

Twice Peeling Rate(%)

Weight(kg)

Dimension(mm)

MTPS18R

2-2.5

18.5-22+2.2

800-1200

3660-3720

65

95

760

1935×735×1892

MTPS25R

3-4

22-30+2.2

1000-1500

3660-3720

65

95

805

2013×693×2222

MTPS30R

4-6

37-45+2.2

2600-3400

4500-5500

65

95

1050

2191×950×2222

MTPS25R×2

6-8

44-60+3

4000-6000

1800-2100

65

95

1500

2033×1450×2222

MTPS30R×2

8-12

74-90+3

5000-7000

4500-5500

65

95

1950

2332×1450×2222