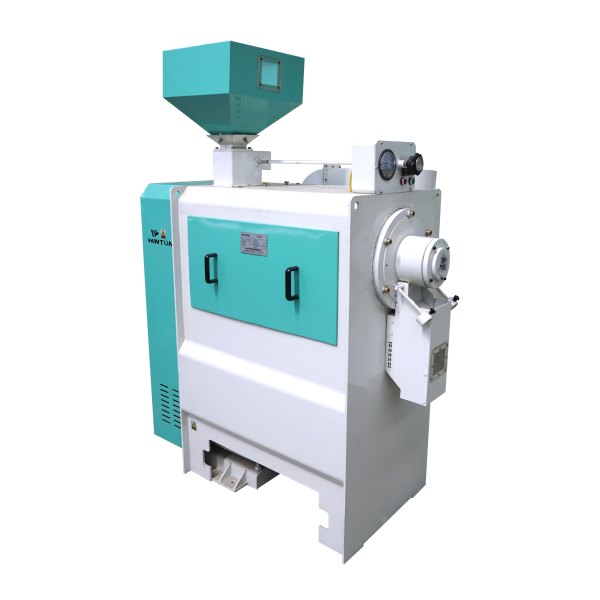

China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

Based on the characteristics of wheat (hard bran and starchy endosperm), WinTone has developed the HTX Series Emery-Roller Wheat Peeling Machine. In wheat flour processing, it can remove 2-3 layers of wheat bran as required, reducing the workload of subsequent milling equipment. It also effectively eliminates surface impurities and mycotoxins, lowering the ash content of finished flour while enhancing its whiteness and purity. When combined with an iron-roller polishing system, it produces high-quality wheat kernels products, making it one of the most popular wheat processing machines on the market.

Working Principle

The HTX wheat peeling machine operates on the principle of mechanical friction and impact. Wheat raws are fed into the peeling chamber, where the high-speed rotating emery roller and peeling plate generate friction and impact forces to separate the bran from the endosperm, achieving efficient peeling.

Feature

1. High Peeling Efficiency

With advanced mechanical design and manufacturing technology, the HTX wheat peeling machine ensures fast peeling speed and high processing efficiency, significantly improving production capacity while reducing labor costs.

2. Premium Product Quality

The peeling process preserves the wheat germ and nutrients, resulting in smooth, bright-colored wheat kernels that enhance the visual and nutritional quality of end products.

3. Excellent Adaptability

Suitable for various wheat varieties and moisture levels, the machine can be adjusted in parameters and configurations to meet different production needs, ensuring stable and efficient operation.

4. Energy-Saving & Eco-Friendly

Incorporating energy-efficient technology and environmentally friendly materials, the HTX wheat peeling machine reduces power consumption and minimizes environmental impact, complying with green manufacturing standards.

Finished Product

Technical Index

Type

Yield(t/h)

Power(kw)

Air Suction(m³/h)

Wind Pressure(pa)

One Peeling Rate(%)

Twice Peeling Rate(%)

Weight(kg)

Dimension(mm)

HTX18

2-2.5

18.5-22+2.2

800-1200

3660-3720

65

95

760

1935×735×1892

HTX25

3-4

22-30+2.2

1000-1500

3660-3720

65

95

805

2013×693×2222

HTX30

4-6

37-45+2.2

2600-3400

4500-5500

65

95

1050

2191×950×2222

HTX25×2

6-8

44-60+3

4000-6000

1800-2100

65

95

1500

2033×1450×2222

HTX30×2

8-12

74-90+3

5000-7000

4500-5500

65

95

1950

2332×1450×2222