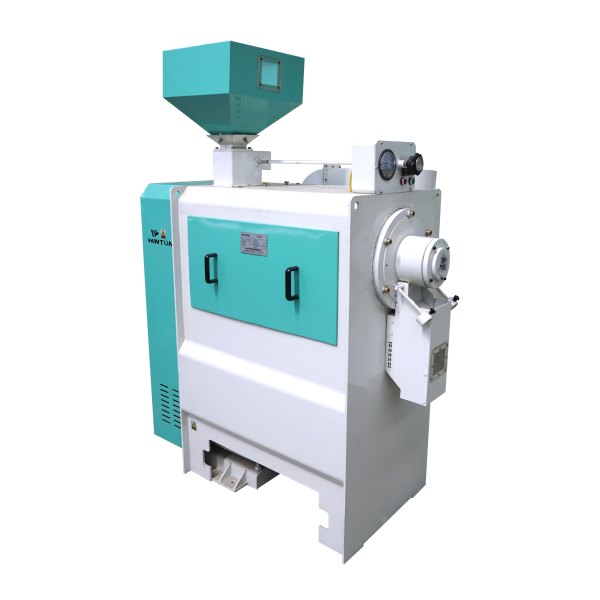

China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

Highland barley belongs to the barley category and is a highland grain, used mainly to make tsampa and alcohol. Today, it is used to make beer (Lhasa Beer), flour, bread, cakes or noodles. The hull of highland barley is extremely hard, making it difficult to remove. Traditional hulling equipment designed for rice often fails to effectively strip the hull from highland barley.

Working Principle

WinTone' s HTQ series highland barley hulling machine adopts a layered peeling design concept. Specifically tailored to the characteristics of highland barley, it is equipped with emery rollers that offer high strength and excellent friction, ensuring the integrity and cleanliness of the hulled barley meet diverse user requirements. The material is conveyed by the screw propeller to the peeling chamber which is at the machine’s core part. It utilizes the emery with high speed rotation and cuts and rubs the grain skin continuously, which destroys the bonding strength among grain skin, material skin, and makes grain skin separated gradually.

Feature

1. Good peeling effect

The machine is used in grain pearling process of grain processing line as well as primary and further peeling process in beer and feed factories.

2. Efficient and energy-saving

The HTQ series barley hulling machine has high peeling efficiency, high yield, durability and stability.

3. Dust removal system

It has the aspiration and dust removal system outside, which ensures the best sanitary conditions.It can be used in series or in parallel in complete processing line according to technological demand.

4. Easily maintained and operated

It has quick-replaceable sieve plate and other parts. The durable emery roller and less abrasion parts make the equipment easily operated and maintained.

Finished Product

Technical Index

Type

Yield(t/h)

Power(kw)

Air Suction(m³/h)

Wind Pressure(pa)

One Peeling Rate(%)

Twice Peeling Rate(%)

Weight(kg)

Dimension(mm)

HTQ18

2-2.5

18.5-22+2.2

800-1200

3660-3720

65

95

760

1935×735×1892

HTQ25

3-4

22-30+2.2

1000-1500

3660-3720

65

95

805

2013×693×2222

HTQ30

4-6

37-45+2.2

2600-3400

4500-5500

65

95

1050

2191×950×2222

HTQ25×2

6-8

44-60+3

4000-6000

1800-2100

65

95

1500

2033×1450×2222

HTQ30×2

8-12

74-90+3

5000-7000

4500-5500

65

95

1950

2332×1450×2222