China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

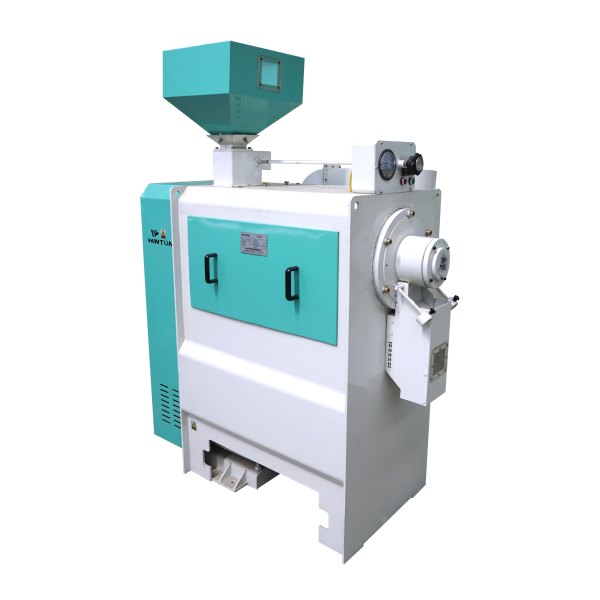

HTD Series Emery Roller Barley Huller is a patented equipment developed by WinTone machinery specifically for the hulling and peeling of barley, addressing the challenges posed by its hard husk. With a single-pass hulling rate exceeding 95%, it can further refine barley through additional peeling and whitening to meet diverse requirements. Equipped with a high-strength (main shaft) and high-wear-resistant (emery roller), it ensures continuous operation and extends service life.

Working Principle

The specially designed emery roller, with its sharp abrasive particles, grinds away the husk, while friction between the barley and the peeling sieve facilitates complete hull removal. Simultaneously, the bidirectional air intake from the main shaft, combined with a powerful bran-aspiration system, forces the husk to separate from the barley and discharge through the sieve pores. An exhaust air device at the outlet reduces the temperature of the finished product.

Feature

1. High Hulling Efficiency

Proprietary technology ensures even force distribution on grains, improving hulling rate, reducing breakage, and delivering superior peeling results.

2. High Capacity & Low Energy Consumption

Processing capacity ranges from 1 to 10 tons/hour, with energy consumption only half that of traditional hullers, ensuring high productivity and low power usage.

3. Wide Application

Suitable for both edible-grade and feed-grade barley processing.

4. Eco-Friendly Design

Employs a pure dry-peeling method, enabling dust-free production. The husk removal rate can be adjusted based on customers' quality requirements for the final product.

Finished Product

Technical Index

Type

Yield(t/h)

Power(kw)

Air Suction(m³/h)

Wind Pressure(pa)

One Peeling Rate(%)

Twice Peeling Rate(%)

Weight(kg)

Dimension(mm)

HTD18

2-2.5

18.5-22+2.2

800-1200

3660-3720

65

95

760

1935×735×1892

HTD25

3-4

22-30+2.2

1000-1500

3660-3720

65

95

805

2013×693×2222

HTD30

4-6

37-45+2.2

2600-3400

4500-5500

65

95

1050

2191×950×2222

HTD25×2

6-8

44-60+3

4000-6000

1800-2100

65

95

1500

2033×1450×2222

HTD30×2

8-12

74-90+3

5000-7000

4500-5500

65

95

1950

2332×1450×2222